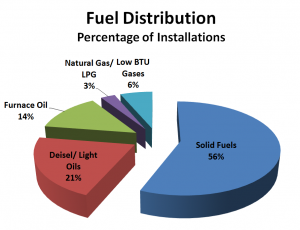

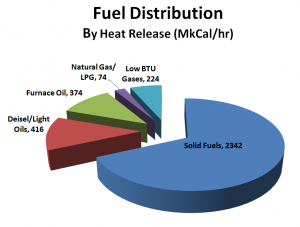

Singhania System Technologists Pvt. Ltd. has installed over 150 Swirl Flame Rotary Kiln Burners in India & abroad. The largest capacity of the Rotary Kiln Burner manufactured so far is 147 MKCal/hr. on a 11,000 TPD Rotary Kiln which used lignite as a fuel for a Cement Plant. The Swirl Flame Kiln Burner has a proven track record for satisfactory performance on low grade pulverised Coal, Pet coke, Lignite, Agro-waste, alternative fuels, Low BTU gases, LNG, Natural Gas, Fuel Oil & various liquid waste fuels. The Burners are customized to suit combination firing with minimum amount of primary air i.e. 6 to 7% depending on the applications.

Swirl flame kiln burners designed by Singhania System Technologists Pvt. Ltd. come as a complete package with channels for different fuels, Overhead/Ground mounting trolleys, pilot gas burner, ignition system, and PLC/ relay based burner management system as required by our customers. The burners come equipped with a highly sophisticated nozzle that ensures proper mixing of air and fuel, provides a stable flame front and allows adjustments for flame momentum and flame length.

Singhania System Technologists Pvt. Ltd. has designed, manufactured and commissioned swirl flame kiln burners for very low calorific fuels, kiln burners working with gaseous fuels available at very low pressures and kiln burners working with fuels having high amount of tar and abrasive content. Even the most difficult to burn fuels have been fired successfully by our burners. Multi-fuel Kiln burners are another specialty of Singhania System Technologists Pvt. Ltd., in which multiple fuels as required by the customer can be fired simultaneously in the burners in various ratios. Our multi-fuel kiln burner systems can also be designed for firing each of the fuels independently.

Our Swirl Flame Kiln burners have found wide acceptability within the cement, paper, iron ore pelletisation, refractory and mineral-processing industries.

High flame momentum

High flame momentum Air assisted type

Air assisted type