With its vast knowledge and experience in the combustion engineering field, Singhania System Technologists Pvt. Ltd. offers a wide range of burner solutions for different applications and multiple industrial requirements. Industrial Burners designed by Singhania System Technologists Pvt. Ltd. support firing of both single fuel and combination of multiple fuels.

Industrial Burners

0

0

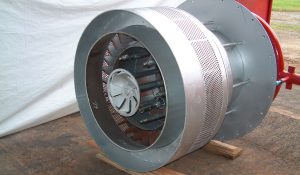

Register Burners are custom built Burners designed and manufactured with rugged construction to supply an intensely mixed air fuel mixture into a furnace for maximum combustion effectiveness. This thorough mixing is achieved by the adjustable rotational air momentum & fuel injection pattern. Pulverised Solid fuel is injected between the two air stream through a specially designed injector located either between the air streams or with Burner axis.

These burners utilize a wide variety of preformed Refractory tiles to provide flame shaping. They can utilize different type of atomizers & gas spuds. Whether installed in industrial furnaces, Boilers or fired heaters, Register Burners by Singhania System Technologists Pvt. Ltd. provide great versatility and long trouble free service.

Solid fuel register burners designed and manufactured by Singhania System Technologists Pvt. Ltd. are of proven design and are operating successfully.

SALIENT FEATURES:

- Low Air Pressure Drop.

- Low Power Consumption.

- Wide Turn Down.

- Multi Fuel Application includes Oil, Gaseous and Solid Pulverised Fuels.

- Can work on 10% to 100% Excess Air.

- Flame Stabilizer for stable flame front at all firing rate.

- Single Air Flow or split Air Flow Design.

- Pre-formed Refractory Throat tiles to achieve desired flame shapes.

- Adjustable multi louvers to adjust air spin for optimum air mixing.

FIRING RANGE:

1MKCal/ Hrto 50 MKCal/Hr.

Singhania System Technologists Pvt. Ltd.’s Process Burners are high performance advanced Burners designed specifically for Process Heaters, Furnaces & Boilers. These Burners are suitable for single Burner or Multiple Burner applications. Burners can fire multiple fuels in combination or individually as desired by operators.

The Combustion air is divided into two streams of air, which flows parallel to each other. The core air, which flows past the spinner, develops a strong recirculation vortex in the Burner Throat. The annulus air, which is introduced over the core air also flows past an air spinner and produces a turbulent air zone. Finely Atomised Fuel jets emitted from a proprietary designedAtomiser / Gas Spud of Singhania System Technologists Pvt. Ltd. are distributed uniformly into these two air streams effecting an intense air fuel mixing. This intense mixing ensures efficient and complete combustion of any fuel.

SALIENT FEATURES:

- Multi Burner, Multi Fuel Firing Capabilities.

- Horizontal, Vertical (any position) and inclined mounting.

- Rugged construction, no moving parts and longer life.

- High Combustion Efficiency.

- Lower Emissions.

- Complete Combustion with negligible CO at 1.5% to 2.0% Excess air.

- Higher Turn Down capabilities.

- Custom Design for superior performance to meet wide variety of applications.

- Burners are provided with PLC Based Burner Management System.

- Flame Monitoring by UV / IR Flame Sensors of proven design.

- Pneumatic / Electrical Damper Controls for Combustion Air Flow Regulations.

FIRING RANGE:

Firing Capacities from 0.5 MKCal/hr. to 15 MKCal/hr.

Cement Industry uses Calciner Burners to have the precalcining of Raw Meals. In general the heat output through Calciner Burners is approximately 60 – 65% of total heat input for the calcination (clinkerisation) process. Singhania System Technologists Pvt. Ltd. design & manufacture Calciner Burners for any fuel such as Liquid, Gas and Solid Fuels. These Burners can work on a single fuel or with multiple fuels in any combination as desired.

Depending on the design of Pre-Calciner and plant capacity, the number of Calciner Burners can range from 2 to 8. For initial startup, Calciner Burners are provided with Auto-ignition system, fuel oil lancer gun & flame management & BMS system. The Burner can be provided with wide firing turndown; say 1:10 or more so that it can assist for curing of newly installed refractory lining. The Burners can be installed on ground / overhead trolley carriers for easy removal & maintenance.

Similar to Calciner Burners, Tertiary Air Duct Burners are supplied to heat up the Duct Gases. These Burners are also having the same features as Calciner Burners and are also provided in down fired construction.

ACCESSORIES:

- Auto Ignition Gas Pilot System.

- Lancers for abrasive & spent Fuel.

- Overhead / Ground Trolleys

- Flame Safe Guard & Burners System

FIRING RANGE:

0.5 MKCal/hr.to 60 MKCal/hr. per Burner.